PCB Assembly

Thousands of printed circuit boards are assembled at Hi-Tek every month.

This

includes through-hole technology, surface mount technology, and mixed boards.

PCB Assemblies are

built

to IPC standards using precision equipment.

SERVICE DETAILS

Why Hi-Tek Electronics?

- New Customer? No setup costs and no stencil charge on your first Assembly!

- Flexibility - Full Kit, Partial Kit or Turnkey. We will work with you to provide exactly what you need!

- Speed - 5 or 10 Day Turn Time. Four available SMT lines to keep your order moving along and on time!

- Quality - Advanced X-Ray and 3D AOI makes sure everything is up to spec!

Contact

3915 Fairview Industrial Dr.

Suite 150

Salem, OR 97302

United States

Toll Free: 1-800-364-9257

Local: 503-364-9257

Surface Mount and Through Hole PCB Assembly

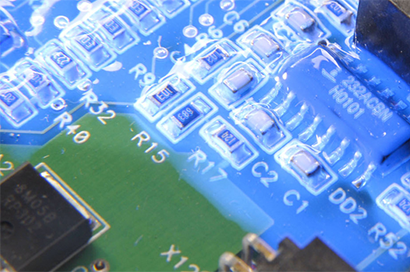

Surface Mount PCB Assembly

Our surface mount department is equipped with state-of-the-art equipment and staffed with trained and qualified professionals. High-speed placement machines with quick changeover capabilities make any job cost-effective. In addition, skilled prototype assembly technicians can hand-build one-of-a-kind prototypes to your specifications.

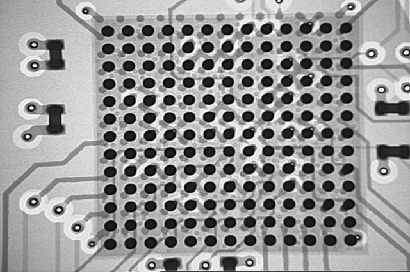

Through Hole PCB Assembly

Hi-Tek also has full Through-Hole assembly capabilities. For larger order quantities, or assemblies with very high part counts, boards may be soldered using one of our computer-controlled wave solder machines. We have both lead and leadfree (RoHS) machines available. After solder inspection, circuit boards are washed with deionized water using a highly efficient aqueous washing system. For prototype work, or boards that require additional components to be added, assemblies are hand soldered by our skilled technicians, using either a water soluble or no-clean process, as requested.

Surface Mount PCB Assembly

- 4 SMT Lines

- Paste or glue screen printing

- Automated component placement

- Pre-flow visual inspection

- Convection reflow soldering

- Automatic Optical Inspection (AOI)

- Manual assembly and hand-adds

- Visual inspection

- Aqueous washing

- ESD packaging and shipping

Through Hole PCB Assembly

- Component preparation

- Component insertion

- Pre-flow visual inspection

- Lead and Lead Free Wave Solder

- Secondary assembly

- Visual component and solder joint inspection

- Final QC Inspection

- ESD packaging and shipping

UNDER THE HOOD

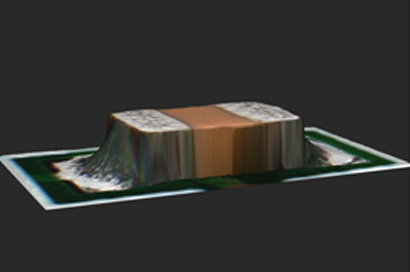

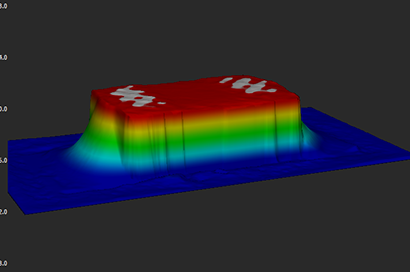

3D AOI and X-Ray Inspection

As technology continues to evolve toward more advanced miniature packaging, PCB density and complexity has increased dramatically. We have added 3D inspection technology to ensure your product arrives with the highest quality!

Extra Value

ADDITIONAL SERVICES

With Hi-Tek we have you covered. Literally! We have special services such as conformal coating.

CONFORMAL COATING

Conformal coating is a protective coating or polymer film 25-75µm thick (50µm typical) that ‘conforms’ to the circuit board topology. Conformal Coating protects your PCB from moisture, dust, salt, chemicals, temperature changes and mechanical abrasion.

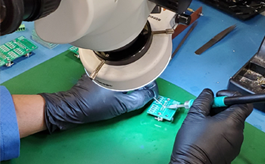

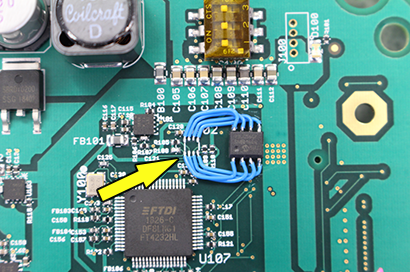

MODIFICATIONS

During the prototype period there could be several upgrades that need to occur. We understand that deadlines and quick turns are important. In many situations we will be able to perform modifications to components or assemblies, such as adding jumper wires, on-site, saving valuable time for our customers.

TESTING

Hi-Tek offers inline or completed PCB assembly testing. We require the customer to provide the test fixtures and process instructions. That way we can test the individual requirements needed by each customer to their specifications. Currently we are testing boards for conductivity, power up, final functionally including displays, LEDs, buttons etc… You provide the test equipment we will conduct the test!

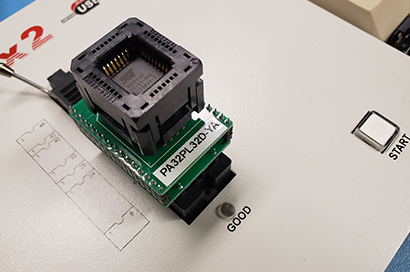

PROGRAMMING

No need to go to another supplier to program your ICs or EPROMS. We have on board chip programming capability using multiple firmware platforms – J-Link JTAG, SX Key, Microchip, and Altera. We also have Intelligent Universal Programmers for EPROMS – ChipMax and EMP-21.